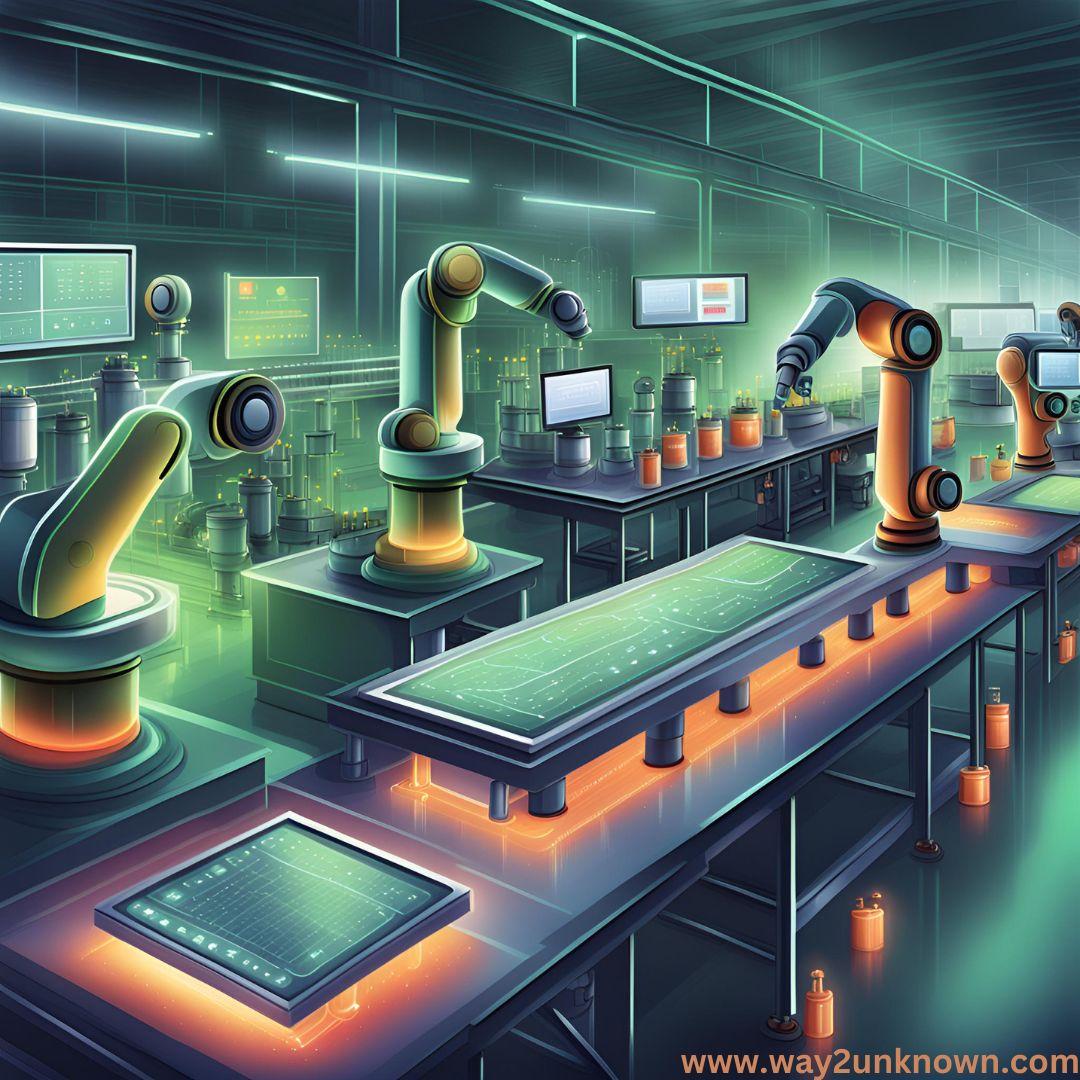

From Defect Detection to Perfection: How AI Transforms Quality Control

In the manufacturing industry, maintaining high quality and minimizing defects are critical for ensuring customer satisfaction and reducing production costs. Artificial Intelligence (AI) is transforming quality control and defect detection processes, making them more accurate, efficient, and reliable.

AI-driven quality control systems utilize advanced machine learning algorithms and computer vision technology to inspect products and identify defects with remarkable precision. Traditional manual inspection methods are often time-consuming and prone to human error, leading to inconsistent results. In contrast, AI systems can analyze thousands of data points and images within seconds, consistently applying the same rigorous standards without fatigue.

One of the key benefits of AI in quality control is its ability to learn and improve over time. Machine learning models are trained on vast datasets containing images of both defective and non-defective products. As these models are exposed to more data, they become better at distinguishing subtle differences and identifying even the most minute defects. This continuous learning process ensures that AI systems are always up-to-date with the latest quality standards and defect types.

Furthermore, AI-powered defect detection systems can operate in real-time, providing immediate feedback during the manufacturing process. This capability allows for the swift identification and correction of defects, reducing waste and preventing defective products from reaching the market. By catching issues early, manufacturers can save significant costs associated with recalls, returns, and rework.

AI also enables predictive quality analytics, which can forecast potential quality issues before they arise. By analyzing patterns and trends in production data, AI can identify factors that contribute to defects and suggest process improvements to mitigate these risks. This proactive approach enhances overall product quality and boosts manufacturing efficiency.

In conclusion, AI is revolutionizing quality control and defect detection in the manufacturing industry. Its ability to perform precise, real-time inspections and continuously learn from new data ensures superior product quality and reduces production costs. As AI technology continues to advance, its role in quality control will only become more integral, driving the manufacturing industry toward greater efficiency and excellence.